Graphite has a wide range of applications, with many excellent properties, are very popular in many processing areas, the introduction of a set of high capacity and efficiency graphite superfine mill will be powerful weapons and equipment to promote the entire graphite industry rapid and healthy development for the graphite factory.

1. Graphite use overview

“Graphite” It is mineral and is not very active chemical properties, meanwhile it has a certain degree of corrosion resistance, graphite exists in a variety of ways, and the appearance is also different. No matter how the progress of the times, how society develops, and graphite always has a wide range of applications in our lives. Graphite is refractory because of its high-temperature properties. For example, crucibles used in the metallurgical industry are made of graphite. Graphite can be used as a conductive material, for example, in the electrical industry, carbon rod, mercury positive rectifier, brush, etc. are made of graphite. It is a sensible choice to use graphite as a wear-resistant and slip-resistant material instead of a lubricant. Graphite is often used as a lubricant in mechanical production. We all know that lubricants cannot be used at high temperatures and pressures. Graphite is different; graphite can be used in high temperature environment. With further development of the society, the development and utilization of graphite will be greatly enhanced.

Graphite will also play a greater role in the national economic construction and become a useful non-metallic mineral for further promoting the development of the industry.

2. What kind of ultrafine grinding mill is used for graphite factory?

In the field of ultrafine milling machine, Fujian Fengli is a representative high-quality manufacturer, Fengli specializes in manufacturing ultrafine mill, and has its own technological advantages in powder making industry, the ultrafine grinding mill equipment is titled as China’s ultrafine powder processing energy saving new equipment by the China Association of calcium carbonate certification, which can greatly reduce the entire investment costs and enhance the market competitiveness for investors.

In graphite factory preparation, Fengli production of graphite ultrafine mill equipment is more in line with the needs of the development of the industry, with many advantages and features such as grinding, impacting and other mechanical crushing properties, processing 325-2500 mesh high quality powder, mainly consist of main mill, feeder, grading machine, blower, pipe device, storage hopper, electronic control system, collecting system, etc., under negative pressure state of production, with increased efficiency dust collector can achieve dust-free working environment; The use of semi-automatic control of a unique process, a substantial increase in production efficiency, main mill base using the overall casting structure, not only to ensure the structural strength, but also good shock absorption performance, small vibration, smooth operation, is the preferred fine grinding equipment for graphite plant.

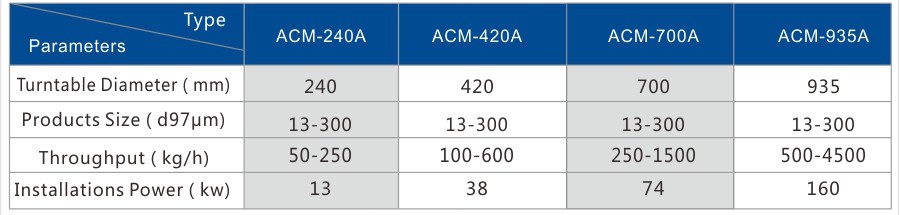

Fujian Fengli graphite ultrafine grinding mill: ACM ultrafine grinding mill

[Maximum size of feed]: ≤10mm

[Production capacity]: 0.5-6.5t/h

[Finished Fineness]: 325-2500mesh

[Features]: 1.Built-in separation mechanism-preventing over-grinding. 2.Able to produce uniform granules of required sizes by adjusting the speed of the stage-separation wheel(s) or by adjusting the strength of the blower(s). 3.Powerful blowing and strong self-cooling capability, suitable for grinding heat-sensitive materials. 4.Different grinding accessories/devices are used according to the hardness of the material being ground; different types of materials (alloyed carbon steel, stainless steel, ceramics etc) are available for the Machine’s inner linings and product extracting system, meeting the needs of different industries. 5.Both manual and programmable auto-controlled machines available.

[Focus areas]: Focus on dolomite, magnesite, manganese ore, gypsum, calcite, barite, fluorite, marble and other Mohs hardness below 7 and humidity less than 6% non-metallic mineral ultra-fine processing and AC foaming agent, carbon black, sulfur and other chemical material grinding, chilli, spice, dried fruit, dried vegetable, salt, sugar and other food grinding. the equipment with a number of countries patented technology, performance reached the national leading level.