No, your machine is not broken – the thread is at fault!

I spent all day yesterday trying to find the culprit of these thread pulls. Surely, the bobbin thread is catching on something! I polished the needle plate, including inside the needle hole. I polished the shuttle, inside and out, the shuttle spring and the cradle. I polished the race. I changed the needle. I changed the foot and polished it underneath. I even polished the tips of the feed dogs! My machine has never been so polished!

I changed the bobbin, that is, I wound a new one using the thread from the old one. And then it dawned on me: the thread!

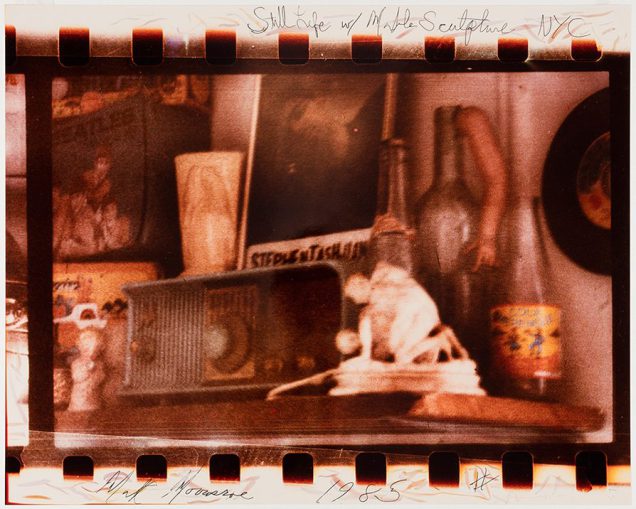

Look how it is twisting!

Good Lord! What’s with that great big twisted loop?

This is a vibrating shuttle machine which I am using on low tension to sew stretch cotton with a flexible seam. So when the thread is pulled up from the shuttle, the twisted loop simply slips through as if it were a knot! The machine is not bothered by such stuff, so it just continues sewing…

So what would happen in a round bobbin machine that sews with higher tension? You’d think the tension would straighten out the twists, but the result is in fact even worse: it chokes. I tried several machines with different mechanisms – the same effect. Sure, on some it happens less often than on others, but they all suffer from the bobbin suddenly being pulled in the wrong direction, there’s a big crash, and either you break a needle, or get a rat nest on the bottom, or a pull, but something awful inevitably happens.