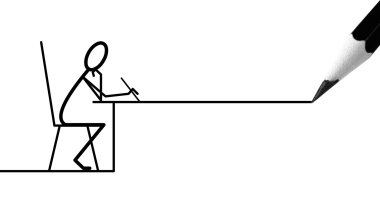

In Steve Blank’s, Why the Lean Start-Up Changes Everything, the successful entrepreneur and investor in start-ups claims that we now have the tools, environment, and knowledge to build lean starts-ups. Entrepreneurs and businesspeople are seeing new successes in this model of turning their ideas into reality. This critical difference between the process of the past and this new shiny model can be compared to an artist getting their drawing from their brain to paper. Instead of being inspired with an idea, and trying to find a stencil from a book, the artist is now able to free hand sketch their design and let the idea develop into its full true potential on the canvas.

One matter that resonated with me from Blank was the idea that if a business wants to be successful today they need to move away from making existing business models more efficient, and begin making the process of going from creative idea, to business product more efficient. Furthermore, Blank’s suggestion of businesses “Stealth Mode” becoming less popular also made sense. In terms of reaching more desirable results, customer feedback and constant revision is more valuable than secrecy and measured unveilings. Finally, Blank’s explanation of the 3 key principles of the lean method delivered a clear, concise idea of what distinguish these businesses from others.

The first key principle of a lean start-up, the business model canvas, is a sketch or diagram of how a company is going to establish itself as an asset for its customers. The second key principle of a lean start-up is customer development. This principle directly connects to why “Stealth Mode” of business is disappearing. Users’, purchasers’, and partners’ feedback on the business model is too valuable not to make it a priority. The final key principle of lean start-ups is one that I have the most real-world exposure to. Blank defines agile development as the iterative process where minimally viable products are created to test.

This past summer I gained first hand exposure to agile development while interning for a Health Insurance company in their Information Services department. Working in an agile environment exposed me to three-week iterations called sprints, daily stand up meetings, and the common practice of developing, testing and redeveloping, all of which have helped me understand the new way products are being created and projects are being managed. Along with Blank and my real-world experience, Briggs also mentions testing, trying, playing, failing, and then trying again. From all this it is clear that we now have the ability to run successful lean start-ups.

For more on lean strategy in the healthcare field I would recommend checking out John Toussaint’s The Toyota Production System: What Does It Mean, And What Does It Mean For HealthCare.

Advertisements Share this: