Agar is derived from the polysaccharide agarose, which forms the supporting structure in the cell walls of certain species of algae, and which is released on boiling. These algae are known as agarophytes and belong to the Rhodophyta (red algae) phylum. Agar is actually the resulting mixture of two components: the linear polysaccharide agarose, and a heterogeneous mixture of smaller molecules called agaropectin. Agar has been used as an ingredient in desserts throughout Asia, and also as a solid substrate to contain culture media for microbiological work. Agar can be used as a laxative, an appetite suppressant, a vegetarian substitute for gelatin, a thickener for soups, in fruit preserves, ice cream, and other desserts, as a clarifying agent in brewing, and for sizing paper and fabrics. The gelling agent in agar is an unbranched polysaccharide obtained from the cell walls of some species of red algae, primarily from the genera Gelidium and Gracilaria. For commercial purposes, it is derived primarily from Gelidium amansii. In chemical terms, agar is a polymer made up of subunits of the sugar galactose.

Fengli agar ultrafine grinding mill integration with grinding and impact mechanical crushing performance is the ideal equipment for processing high-quality 325-2500 mesh powder. This equipment has advantages of small footprint, wide application, simple operation, convenient maintenance, stable performance, cost-effective, energy-saving and environmental protection and other features, and was certified as energy saving equipment by Chinese calcium carbonate, is the best choice for deep processing of graphite, barite, calcium carbonate and other non-metallic minerals.

So, what is the working principle of the agar ultrafine grinding mill? Material was crushed into less than 10mm materials by the jaw crusher, then send by the bucket elevator to hopper, and then sent to the main mill cavity from the feeder quantitative for grinding, the material after multilayer grinding falls down to the grinding plate due to gravity, and been blowing to the top of the main mill for classifying, coarse powder still fall into the main mill for re-grinding, the specifications fineness flow into the pulse dust collector, collected after discharge valve, the wind road is cycle, besides the blower and grinding chamber is pressurized, the rest airflow are under negative pressure, no dust leakage which can ensure clean workshop.

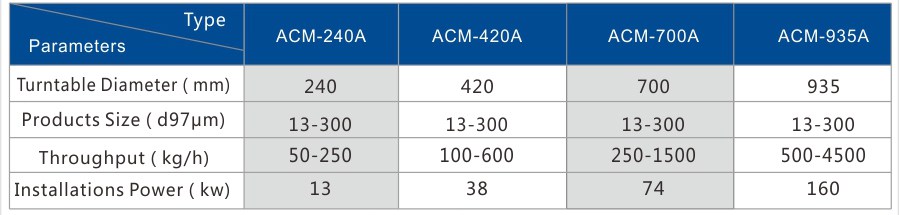

Fujian Fengli agar ultrafine grinding mill: ACM ultrafine grinding mill

[Maximum size of feed]: ≤10mm

[Production capacity]: 0.5-6.5t/h

[Finished Fineness]: 325-3500mesh

[Features]: 1.Built-in separation mechanism-preventing over-grinding. 2.Able to produce uniform granules of required sizes by adjusting the speed of the stage-separation wheel(s) or by adjusting the strength of the blower(s). 3.Powerful blowing and strong self-cooling capability, suitable for grinding heat-sensitive materials. 4.Different grinding accessories/devices are used according to the hardness of the material being ground; different types of materials (alloyed carbon steel, stainless steel, ceramics etc) are available for the Machine’s inner linings and product extracting system, meeting the needs of different industries. 5.Both manual and programmable auto-controlled machines available.

[Focus areas]: Focus on dolomite, magnesite, manganese ore, gypsum, calcite, barite, fluorite, marble and other Mohs hardness below 7 and humidity less than 6% non-metallic mineral ultra-fine processing and AC foaming agent, carbon black, sulfur and other chemical material grinding, chilli, spice, dried fruit, dried vegetable, salt, sugar and other food grinding. the equipment with a number of countries patented technology, performance reached the national leading level.